- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Català

- שפה עברית

- Cymraeg

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Twi

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Tǝlam Kanuri

- Punjabi

- پښتو

- Chichewa

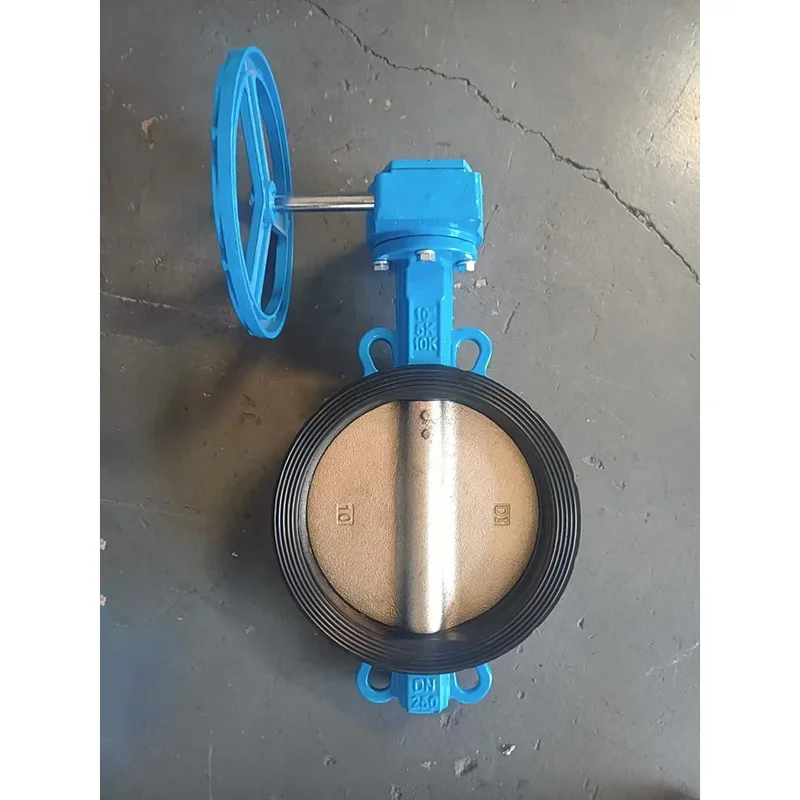

Ta yaya za a magance matsalar rashin daidaituwa na belves?

2025-09-01

Yadda za a magance matsalar rashin daidaito naball bawul?

Kwallan belves ana amfani da su sosai a masana'antun masana'antu da kuma amfani da kullun saboda fa'idar su na buɗewa da sauri, da sauransu ba za a iya magance wannan ba?

Dabawalar ballYana da talauci mai kyau, wanda zai iya zama saboda lalatattun rufe hanyoyin. Amfani da lokaci mai tsawo ko kasancewar haramtattun barbashi a cikin matsakaici na iya satar surface, shugaban gazawar gazawar. Idan kawai ɗan ƙaramin ƙyallen, ana iya amfani da kayan aikin nika don niƙa da gyara madaukakin sealing. Da farko, zaɓi yanayin raunin da ya dace ya mamaye shi kuma a ko'ina amfani da shi ga sealing farfajiya. Bayan haka, yi amfani da kayan aikin nika don niƙa a cikin wani shugabanci da matsin lamba har sai shimfidar secking yana da laushi da lebur, maido da hatimin aikin. Idan farfajiyar ne mai rauni sosai, tare da fasa ko sikelin zurfi, ya zama dole don maye gurbin ƙa'idodin hatimin don sake kyakkyawan ɗaukar hoto.

Sako ne kujerun bawul na iya haifar da talauci na bawul. Yayin budewar Balbors da kuma rufe kujerun belves, bawul din na iya kwance saboda rawar jiki, wanda ya haifar da karuwa a cikin rata na hatabi tsakanin kujerar bawul da kwallon. A wannan gaba, ya kamata a rufe bawul din, sannan kuma ya kamata a rarraba bawulen ƙwallon ƙafa don bincika gyaran wurin bawul ɗin. Idan kujerar bawul ɗin tana da alaƙa, zaren za a iya ɗaure ta da kyau; Idan ringin mai riƙe an gyara shi, duba idan ya lalace. Idan ya lalace, maye gurbin ringi mai riƙe da sabon saiti don tabbatar da daidaitaccen wurin da zai tabbatar da ƙwallon.

Bugu da kari, hatimin hatiminball bawulHakanan yana da alaƙa da ingancin shigarwa. Idan bawul ɗin ba ya cikin madaidaiciyar matsayi yayin shigarwa, ko kuma idan danniya bututun zata haifar da bawul din don nakasa, zai shafi hatoring. Kafin kafuwa, a hankali bincika ko ƙayyadaddun bayanai da samfuran bawul ɗin suna biyan bukatun don tabbatar da yanayin kafuwa na tsabta. A yayin aikin shigarwa, ya zama dole a bi hanyar da ta dace da jerin aikin don kauce wa matsanancin yawan ƙwayoyin cuta. Bayan shigarwa, gudanar da gwajin sealing. Idan an samo suturar matalauta, daidaita matsayin shigarwa ko adireshin piplorline data al'amuran a cikin wani lokaci.

Lokacin da hatimin bawul ɗin ba shi da kyau, ta hanyar sanya madaidaicin wurin, ma'aunin bawul, da kuma ɗaukar mafita na hatimcewa kuma tabbatar da yanayin aikinta na al'ada.

Labarai masu alaka

Sabbin Kayayyaki